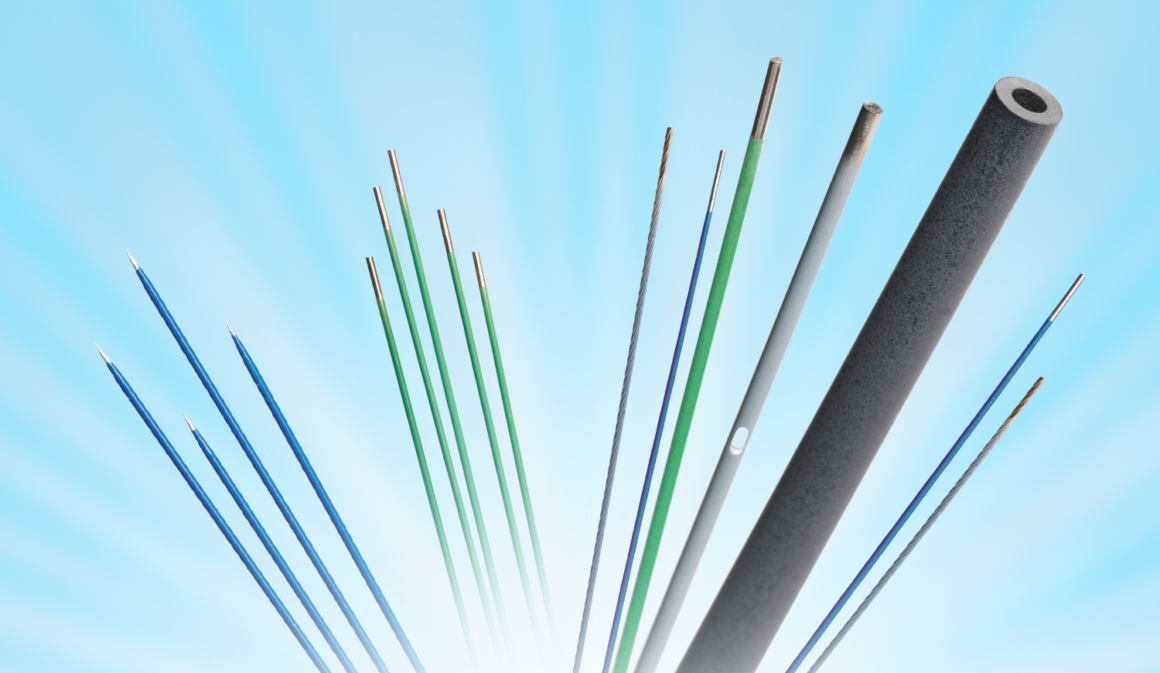

What goes into developing coatings for medical devices? What drives the process? Understanding the factors that motivate manufacturers to seek out new and better coatings – such as our new GlideMed™ PTFE-free coating – and the processes that bring them to fruition can help medical device manufacturers and design engineers appreciate the big picture.

Many products relevant to the medical industry have been discovered practically by luck, fueled greatly by sheer determination, dedication, and (perhaps most importantly) curiosity.

George Osterhout, SSG’s senior advisor and former president, authored an article that was recently featured in Medical Product Outsourcing magazine discussing this topic.

Regulatory Requirements

The article discusses regulatory requirements driving change, in particular, the U.S. Environmental Protection Agency (EPA) restrictions on the use of perfluorooctanoic acid (PFOA) and perfluoroalkyl and polyfluoroalkyl substances (PFAS) – the fluoropolymers used to manufacture PTFE.

To keep pace with ever-changing regulations and device design requirements, innovative coating companies like SSG continuously research, develop, and test new coatings. The article includes two case studies that explore some of the more notable challenges and PTFE-free coating solutions of late.

The Challenges of Coating Nitinol

The first case study illustrates how beneficial a new, water-based, biocompatible PTFE coating solved one medical device maker’s challenge in coating nitinol. Nitinol’s “super elasticity,” combined with its ability to safely hold open vessels while inserting devices such as stents, makes it an invaluable tool for medical professionals, but it cannot withstand the high temperatures required for curing traditional PTFE coatings.

The Science Behind the Creation of a PTFE-Free Coating

Given the success of the low PTFE coating, the question inevitably arose of what would happen if all the proposed regulations against fluoropolymers and PTFE were imposed. It could significantly impact the businesses of all coating suppliers, application and their customers.

The second case study explores the science of PTFE coatings and the process for using established scientific data to reformulate existing proven coatings and create our new low friction, water-based PTFE-free coating – GlideMed™.

Click here to read the entire MPO article.

Contact us for more information about our coating technologies or to discuss your project with our technical consultant.