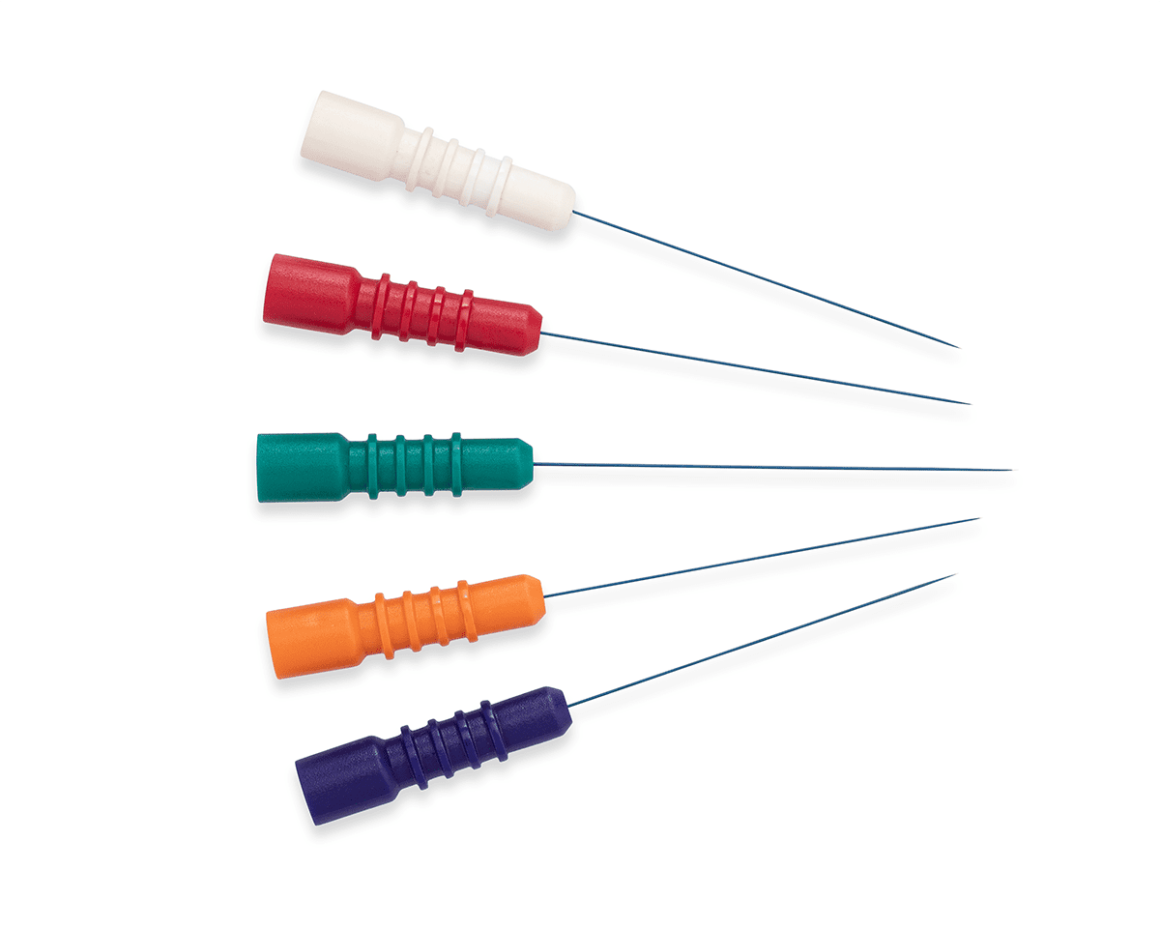

A variety of FluoroMed®, GlideMed® and FluoroBond® coatings along with other low friction PTFE coatings are applied to needles at Surface Solutions Group. The coating solution is based on the needle use requirements. If the needle requires low insertion force or low-friction properties, then we may sample one of our FluoroBond® coatings along with our FluoroMed® or GlideMed® coatings. If the application is on an EMG needle and requires electrical insulating properties, we offer our FluoroMed® coating or a high-build PTFE. All of these medical device needle coatings have been tested and are in use throughout the medical device industry.

Applied coating properties include:

- Low friction properties

- Low or High temperature application and cure temperatures

- Coating thickness from .0001” to 0.002” depending on the coating

- Areas can be marked for identification purposes or the tip of the needle marked to allow for stimulation

- Excellent adhesion properties with any of our coatings

- Inert coatings and gamma stable

- Will not anneal or affect temper of a cutting edge

Contact us to discuss your project with a technical consultant.