Low Friction Coatings for Silicone and Polyisoprene Rubber

Silicone’s popularity for use in medical devices has been growing. This is due to its compatibility with bodily fluids and strong chemical structure. Advancements in medical polymers are also part of this push toward next-generation single-use medical devices, implants and packaging technology.

In order to get the right material, configuration and manufacturing process for a device’s proper end use, it’s key to choose the proper technology to customize the silicone components for the right application. Surface Solutions Group has extensive experience in selecting the right coating for your product’s usage and desired functionality. We can apply the ideal low friction coatings for your silicone and rubber medical applications. We’ll review the advantages and disadvantages of several types of processing techniques for silicone, plus post-fabrication services like coating, sheeting, tubing and packaging.

Silicone Parts & Applications

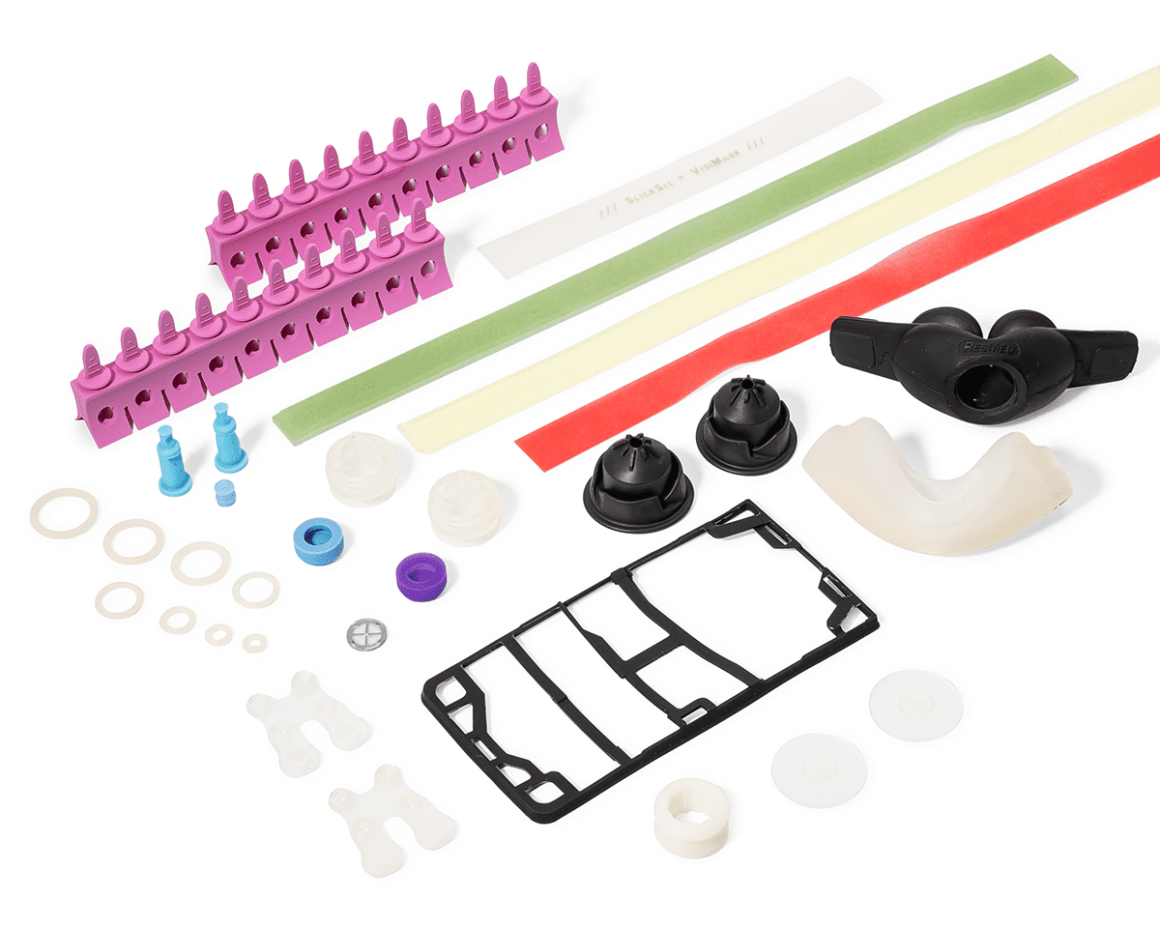

Due to its added durability and flexibility, silicone often has many more medical applications than polyisoprene rubber. In fact, performing many procedures and using many devices simply wouldn’t be possible without the use of medical-grade silicone. A few commonly coated parts include:

- Stents

- Syringes

- Cannulas

- Medical implants

- Hypodermic needles

- Pacemaker leads

- Electrosurgical devices

- Cardiac assistance devices

- Electrosurgical tools

- O-rings

- Medical electronics

- Defibrillator leads

- Seals and gaskets

- Electrosurgical blades

- Introducer tips

- Hearing aids

- Many other silicone parts

Rubber Parts & Applications

When it comes to your rubber parts, we have the low friction medical coatings for rubber to get the job done. Our coatings add low-friction properties to your rubber parts. Rubber surfaces that are normally high friction are transformed into a more durable, low-friction surface. Some of the parts that we coat include:

- Valves

- O-rings

- Tubing

- Molded parts

- Extruded parts

- Many other rubber parts

Eliminate the Stickiness of Silicone Rubber

Surface Solutions Group has developed a totally conformable yet flexible and low friction Slick Sil® LSR medical coating for silicone rubber that is bonded chemically to the silicone substrate. Slick Sil® LSR is a replacement for Parylene, which is a physical bond and tends to crack and peel when the substrate is flexed or stretched. This dramatic low friction coating Slick Sil® for silicone rubber allows designers and engineers to have the benefits of silicone rubber without the high friction surface.

All molded or extruded silicone rubber components can be processed with the SSG Slick Sil® LSR low friction technology. SSG’s Slick Sil® LSR is a great parylene replacement coating that makes silicone slippery.

Slick Sil® Low Friction Coating Makes Silicone Slippery

- When used on catheters, Slick Sil® reduces the friction properties of silicone by 40 – 60%

- Can be applied to 40 – 90 durometer silicone

- Cure temperatures of less than 350 F

- Replacement for Parylene

- Chemical bonding versus mechanical bond to the silicone

- Flexible

Low Friction & Flexible Replacement for Parylene

Slick Sil® LSR is a translucent matte coating designed to reduce the coefficient of friction (COF) and hence, the friction force of molded and extruded silicone elastomers. The ability of the Slick Sil® LSR medical coating for rubber to reduce the surface friction of elastomeric silicone parts enables LIM® (Liquid Silicone Rubber), HCR, and RTV materials to be utilized in areas that were previously closed to silicones due to their high inherent COF.

Key Features:

- Low friction (.31) vs. raw silicone (.65)

- Chemical bond

- Thin film (.0005” – .001”)

- Elastomeric

- Excellent elongation

- Reduces surface dust pick up

- VOC (Volatile Organic Compound) free

- Biocompatible (USP class VI requirements)

- Can be tinted by using silicone compatible pigments

- Anti-microbial properties (optional)

- Disadvantages of Parylene & Silicone Lubricants

- Parylene:

- A rigid coating that cracks on flexible silicone (physical bond)

- Requires time-consuming and expensive vapor deposition process

- No anti-microbial properties

- Silicone Lubricants:

- If not applied correctly, the lubricant can migrate

- Extra cost and step in manufacturing process

- Contamination of other manufacturing areas in facility

- Extremely expensive

- No anti-microbial properties

FluoroMed®-AM Added to Slick Sil® Coating

- An antimicrobial additive for the device sanitization and safety of the patient

- Can be added to our Slick Sil® coating

- Silver ion technology for improved product performance

Contact us today to discuss your project with a technical consultant.