For medical OEMs in need of precision application of coatings for reel-to-reel, continuous wire, Surface Solutions Group (SSG) has the experience, know-how and equipment to make it happen.

Whether the application involves continuous round wire, tubing, or cables, our team takes care to apply Polytetrafluoroethylene (PTFE) coatings to reel-to-reel wires at 0.0001- 0.0003 inches per side to ensure customer specifications are met. We understand the need for precision application of PTFE coatings that provide both column strength and flexibility, allowing the end user to safely and effectively reach the treatment area.

Types of metal and reels SSG has coated include:

- Nitinol and titanium wire and tubing

- Tungsten and stainless steel wire or cable

- 304 V solid round wire, from 0.007″ to 0.040″ in diameter

FluoroWire® Coatings Ideal for Reel-to-Reel

SSG is a leader in the development and application of functional coatings for all types of medical wire, cable and tubing products requiring a low-friction surface value. Our proprietary, PFOA-free FluoroWire® coatings, for example, can be bonded to reel-to-reel, continuous wire, tubing and cable to greatly reduce intravascular friction in medical devices and components such as mandrels, guidewires, catheters, hypotubes, and stents.

For example, FluoroWire® coatings are excellent for providing lubricity and precise coating thicknesses in medical instruments, such as guidewires, control wires and push- and pull-wires used in angioplasty procedures. FluoroWire® reduces friction between the wires and the artery or vessel, as well as any other devices used during angioplasty to provide maximum controllability for the cardiologist performing the operation. We understand that the coating cannot significantly affect the wire’s wall thickness. It must be applied precisely to ensure the coated wire can move easily into and out of very small anatomical passageways.

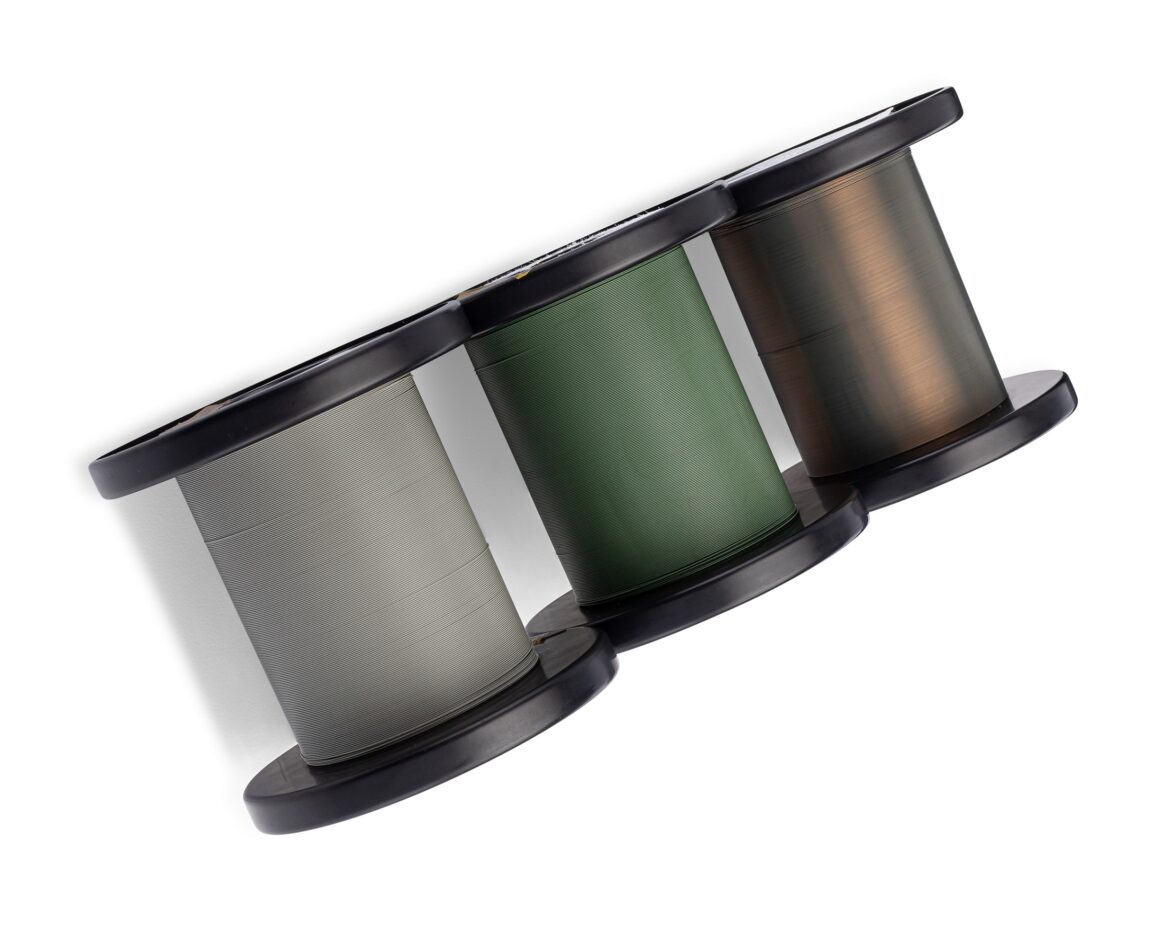

Continuous wire lengths (Diameters of 0.007” – 0.040”), including braided and twisted cable, benefit from uniform coverage, excellent adhesion, and even a variety of color options (ask about custom color availability).

FluoroMed®-AM: Anti-Microbial Coating Technology

For applications requiring anti-microbial, anti-bacterial coating properties, we offer our proprietary FluoroMed®-AM biocompatible coating. FluoroMed®-AM can be added to SSG’s medical coatings, including FluoroWire®, without affecting thickness of application to reel-to-reel, continuous wire and cable products.

Additionally, FluoroMed®-AM anti-microbial applications have been successfully applied on all medical grade metals, plastics, glass, and silicone rubber. All these substrates can have anti-microbial properties with laboratory-tested pathogen kill rates of 99.9%, providing added protection for the patient against infection. Ask your SSG technical consultant about including FluoroMed®-AM in your reel-to-reel coating project.

Leader in the Application of Biocompatible Coatings for Reel-to-Reel, Continuous Wire

Delivering exceptional quality, consistency, and performance is the top priority for SSG coating technicians when coating cut-to-length or reel-to-reel medical tubing, wires, and cables. In addition, SSG has an on-site R&D coating lab that works closely with customers to create innovative coating solutions specific to their application.

Contact us to discuss your project with an SSG technical consultant or request an engineering evaluation for your next medical device project.