With more than six decades of coating expertise, the Surface Solutions Group team is often asked questions about medical grade PTFE coatings their application to a variety of medical devices and components. Here are the answers to some of the more common medical device coating questions we hear.

Q: What is PTFE coating?

A: PTFE, or Polytetrafluoroethylene, is a type of coating renowned for its exceptionally low friction, resistance to chemicals and ability to bond to stainless steel substrates. In fact, PTFE has the lowest Coefficient of Friction (CofF) of any medical device coating to date. PTFE enhances device functionality not only by reducing friction, but also by providing electrical insulation.

Q: How are PTFE coatings used in the medical field?

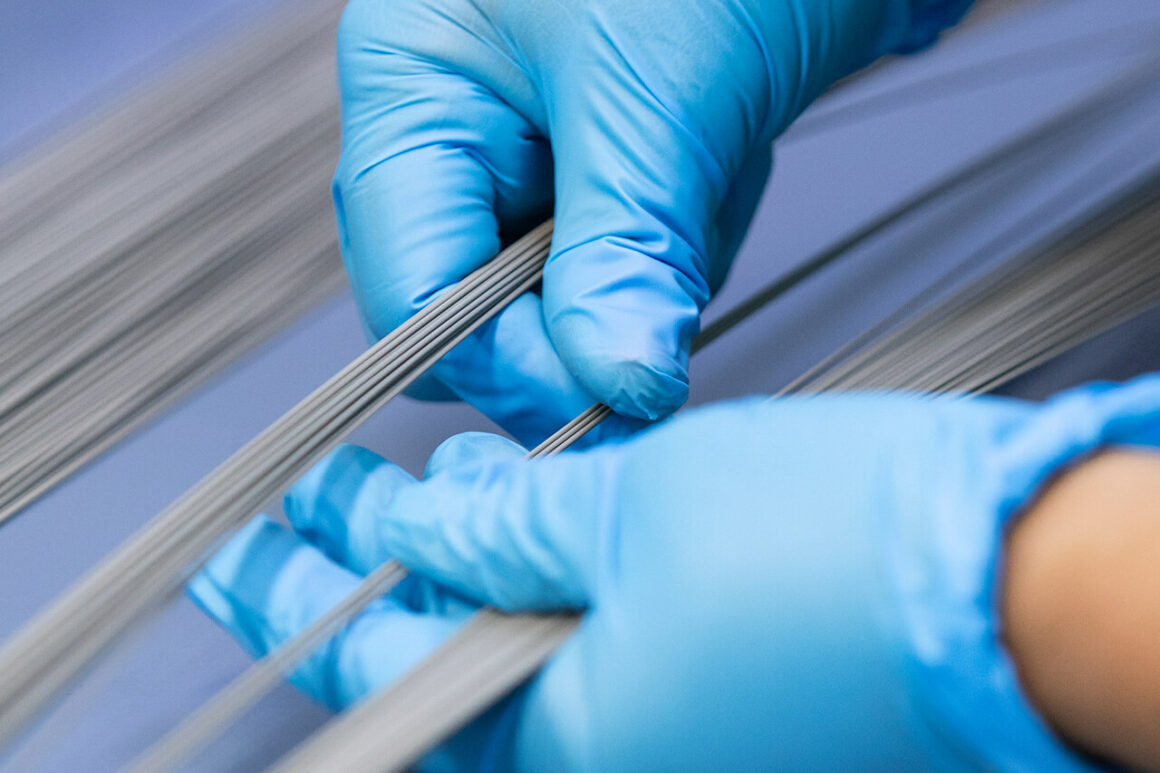

A: PTFE coatings are widely used in the medical field due to their low friction and insulative properties. We apply these coatings to medical devices and components in order to improve the performance of devices such as guidewires, coils, mandrels, needles and hypotubes, ensuring smooth operation and enhanced patient safety, comfort and outcomes.

Q: What range of colors does Surface Solutions Group offer for medical device coatings?

A: Recognizing the importance of differentiation and identification in medical devices, we offer a variety of coating colors, including clear/natural, green, blue, gray, white, purple, black and cream. This variety aids in device identification and functionality. We also offer custom colors for OEMs seeking to differentiate their devices in the marketplace.

Q: Can Surface Solutions Group coat devices of varying lengths and diameters?

A: Absolutely. Our production facility is equipped to handle a wide range of device sizes. For instance, all guidewires and coils are coated within the following parameters:

- Wire diameters starting at .003”

- Discrete wire lengths up to 300 cm

- Reel-to-reel, continuous wire

- Coiled wire diameters from .012″ to .054″

- Individual coiled lengths from 2.55 centimeters to 635 centimeters

Coating parameters for mandrels, hypotubes, solid formed wires, and snap wires as follows:

- Diameters from .007” to .125”

- Cut lengths from 7cm to 300cm

- Solid round, flat, twisted, rectangular and tapered wire

Q: What device substrates can Surface Solutions Group coat?

A: The following are a few examples of some of the substrates that we coat:

- Stainless steel alloys

- Nitinol

- Titanium

- Tungsten

- Silver-plated copper

- Silicone and polyisoprene rubber

Q: What is the durability of coatings provided by Surface Solutions Group?

A: Our coatings are designed for longevity. To increase durability and lubricity, many medical devices and components such as guidewires, hypotubes, probes, blades and needles can be successfully coated with one or more of our 13 medical device coating technologies.

Our FluoroBond® N/N2/N3 is a micron-thin ceramic coating that exhibits a tenacious bond to smooth cutting surfaces such as scalpels and blades. The bonded film has very low surface energy, which reduces cutting force by providing an ultra-low friction coated surface. This allows for a lower insertion force and for cuts to be made smoother, faster, and with resistance.

Q: How does Surface Solutions Group ensure the quality and compliance of its coatings?

A: We adhere to strict quality standards, including ISO 13485:2016 compliance. While the FDA does not directly certify coatings, we ensure our coatings undergo rigorous independent testing, aligning with standards like ISO 10993-1 for biocompatibility. Every year we undergo an external audit, and we’re proud to say that for the past three years we’ve had zero findings.

Q: What kind of support does Surface Solutions Group provide in terms of customization and technical expertise?

A: We always work closely with our clients to understand their unique requirements. Our team of seasoned technicians and engineers is adept at providing tailored solutions, including precise masking and custom coating applications, to meet their specific medical device needs.

Our medical device coating capabilities and technologies allow us to coat products for medical devices that include guidewires, hypotubes, needles, coils, mandrels, and much more. Our coatings are used on a wide variety of metal substrates, silicone rubber, natural rubber, pebax, glass, polymers, and other substrates.

We strive to provide the best medical device coating solutions, and continue to develop new and exciting coatings for the medical device industry, such as our new No and Low PTFE GlideMed™ coatings. Not only can we assist you with your specific application, but we will work to educate you on the different coating technologies we offer, and which would be best for your current and future projects.

Q: How does Surface Solutions Group handle large-scale coating projects?

A: Our 32,000 square foot facility is designed for high-volume production. We coat hundreds of thousands of parts each day for a wide range of medical devices, while maintaining our commitment to quality, service and on-time delivery.

Our focus on delivering high-quality coated medical devices and components has caused us to grow quickly over the years. This allows us to meet customer delivery, quality, and service requirements effectively and efficiently. Our operation includes 11 automated electrostatic spray coating lines, 7 automated dip coating lines, 10 manual and semi-automatic coating cells, a dedicated fast response prototype department, and an airborne dust-controlled environment for application of coatings.

Q: How do I get help figuring out the right coating for my medical device project?

A: Contact us today to speak with an SSG technical consultant.