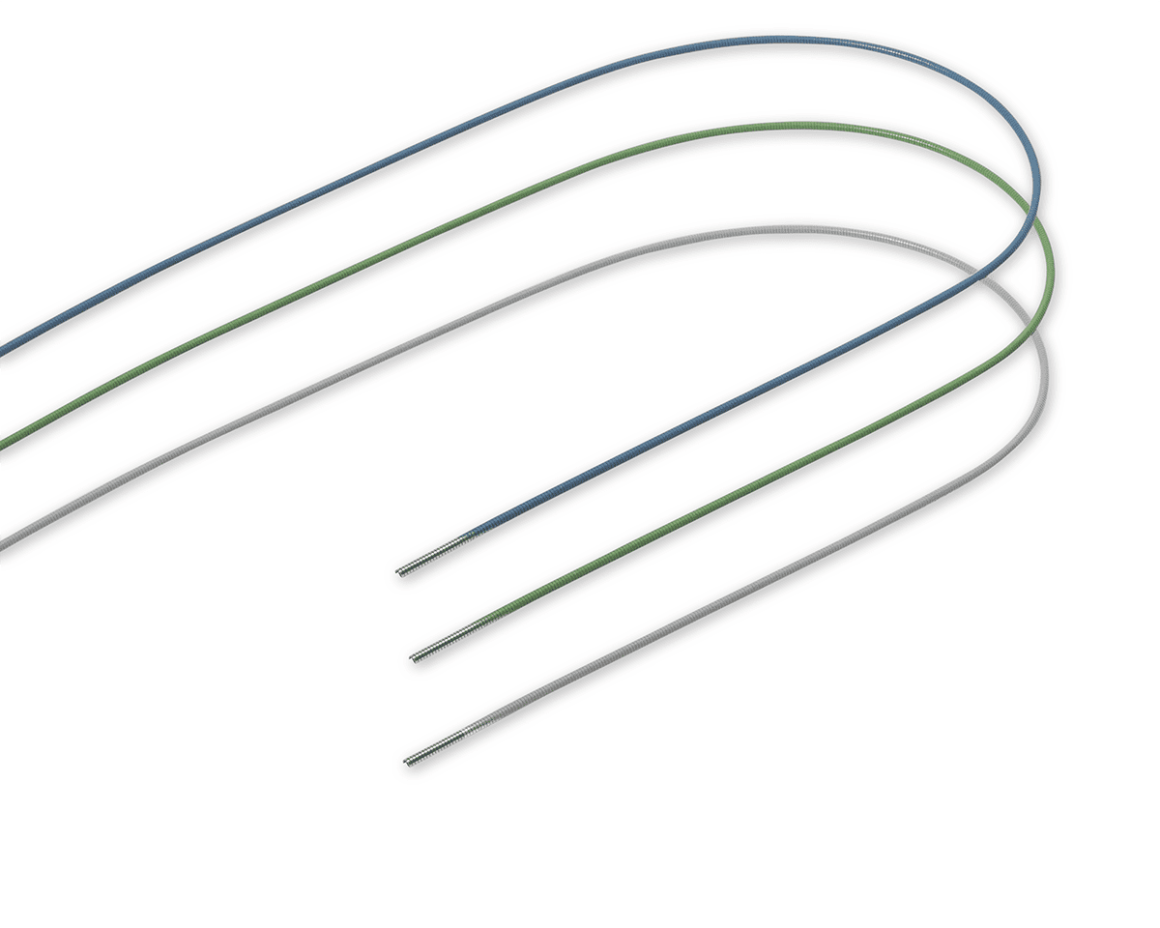

Low Friction Guidewire Coating Services

At Surface Solutions Group, we specialize in applying precise, uniform and consistent coatings to your guidewires, coils, and cables. Your devices and components will be in the hands of our highly skilled, capable and well-trained coating professionals. It’s our job to make sure that your products leave our coating facility with the most consistent and uniform coating. You can count on SSG to deliver high quality coated parts to you lot after lot. We do this by applying the coating on our automated coating lines, using a proprietary system that allows us to apply the exact amount of coating that your parts need to meet your coating specifications. Whether you’re developing new medical devices or improving existing products, you can trust that when you partner with SSG, our coatings will improve your products’ performance and durability.

SSG’s FluoroMed® PTFE guidewire coatings, our GlideMed® Low PTFE coatings and GlideMed® No PTFE/No PFAS coatings all play a crucial role in minimally invasive procedures by providing a low-friction surface that enables smooth, precise movement through complex anatomical pathways. By reducing resistance, these low friction guidewire coatings help medical professionals navigate the body with greater control, minimizing trauma to blood vessels and improving patient safety.

The biocompatibility of SSG’s PTFE coatings further reduce the risk of adverse reactions in patients, making it a trusted choice for medical device design engineers. PTFE coated guidewires are widely used in cardiology, radiology, neurology, and other precision-guided interventions. Their combination of flexibility, durability, and smooth handling allows medical professionals to perform complex procedures with confidence. In addition, SSG’s sustainable advanced GlideMed® Low PTFE and No PTFE coatings support the development of next-generation medical devices, ensuring optimal functionality in critical healthcare applications.

WHY CHOOSE SSG FOR GUIDEWIRE COATINGS?

SSG’s skilled and highly trained coating professionals are dedicated to ensuring the highest levels of quality and care for your guidewires and coils. Our proprietary, custom-design production lines and fixtures are designed to secure your guidewires and protect them during processing. Our advanced automated coating systems apply precision coatings, with the highest levels of accuracy, consistency, and repeatability.

All guidewires and coils are coated within the following parameters:

- Coiled wire diameters from .012″ to .054″

- Individual coiled lengths from 2.55 centimeters to 635 centimeters

- 304 V Stainless and nitinol (as well as 304 V stainless and nitinol combination)

- Complete guidewire assemblies

- Stylets and cables

Contact us to discuss your project with a technical consultant.