GlideMed®: Sustainable, Compliant Low Friction Medical Device Coating

GlideMed® is a sustainable low friction medical coating that is free from harsh chemicals. It is a water-based, biocompatible, environmentally friendly coating that was developed using established, proven coating technology.

Sustainable GlideMed® coatings are available in two formulations: GlideMed®-Low PTFE and GlideMed®-No PTFE, a PFAS-FREE coating for medical devices.

Both GlideMed® coatings offer permanently bonded, low friction properties that are a good, proven alternative to traditional PTFE coatings. Our advanced automation and testing equipment ensures high-quality, consistent, and repeatable application of the coating on an array of medical devices and components.

GlideMed® has excellent adhesion to stainless steel and nitinol substrates and superior durability compared to traditional resin-bonded PTFE coatings. Its low cure temperature of 450F makes it an ideal hydrophobic surface coating for nitinol, with no change to the nitinol activation temperature (Af).

GlideMed® biocompatibility is tested to ISO 10993-5 by third party labs. Further compliance to ISO 10993-5 is the sole responsibility of the design owners.

PFOS-, PFOA- AND HEX CHROME-FREE HYDROPHOBIC COATING

Certain chemicals have come under increased scrutiny by the US EPA (Environmental Protection Agency) and EU MDR (Medical Device Regulation). Medical device manufacturers and their design engineers are increasingly seeking functional coatings that meet or exceed regulatory requirements. GlideMed® is a sustainable, water-based hydrophobic surface coating that is REACH and RoHS compliant. It features:

- No PTFE/No PFAS and Low PTFE Options

- No PFOS

- No PFOA

- No Hexavalent Chromium

- No Harsh Solvents

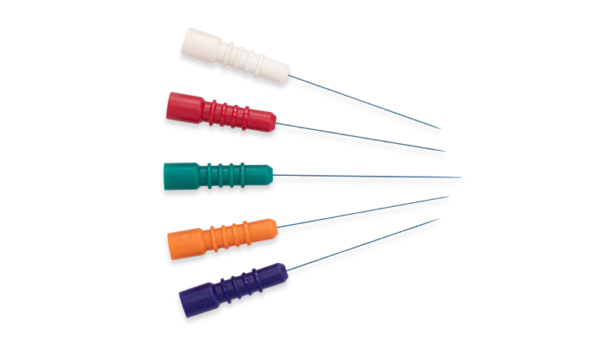

MEDICAL DEVICE APPLICATIONS WITH LOW FRICTION GLIDEMED®

The following medical device applications can benefit from the reduced surface friction of GlideMed®:

- Guidewires

- Needles

- Coils

- Mandrels

- Hypotubes

- Continuous reel-to-reel wire

- Push/Pull wires

- Components and more

APPLY GLIDEMED® TO MULTIPLE WIRE TYPES AND CONFIGURATIONS

- Stainless steel alloys, tungsten, titanium, nitinol, and silver-plated copper

- Round, stranded, flat, twisted, tapered, coils, cables, or tubes

- Discrete lengths up to 300 cm

- Reel-to-reel, continuous length

- Wire diameters starting at .003″

COATING OPTIONS AND KEY FEATURES OF GLIDEMED®

- Two formulations: No PTFE/No PFAS and Low PTFE

- Clear/natural, green, blue, gray, black, and custom colors available

- Applied coating thickness of .0001″ – .001″ per side

- Excellent adhesion and flexibility

- Uniform coverage and thickness

- Smooth, continuous low-friction surface

- No change to nitinol activation temperature (Af)

- Low coefficient of friction (CofF)

- Good insulation properties

- Non-stick properties

- Can be post ground

SUPERIOR QUALITY, EXPERIENCE AND INTEGRITY YOU CAN RELY ON

For all medical and precision applications, the experience and integrity of the coating applicator is of utmost importance. Medical device and component companies choose SSG for our unparalleled, exceptional quality, delivery, and service.

ADDITIONAL RESOURCES

TECH SHEET

Download our tech sheets for printable versions you can share with your team.

QUESTIONS?

Learn more about using sustainable, low friction GlideMed®-Low PTFE or GlideMed®-No PTFE/No PFAS medical device coating for your next project.

OTHER COATINGS

Low Friction Hydrophobic Coatings

Sustainable, Low Friction Hydrophobic Coating

- GlideMed® Low PTFE or No PTFE/No PFAS

Low Friction Hydrophilic Coating

Low Friction Coatings for Rubber and Silicone

Low Friction Coatings for Markings or Identification

Insulative Coatings

- FluoroMed®

- ElectroBond®

- GlideMed® Low PTFE or No PTFE/No PFAS

- VisiBond ®

Specialty Coatings