Surface Solutions Group contributed editorial content to a recent Medical Product Outsourcing (MPO) magazine article about the thrombectomy device market. Our subject matter expert, George Osterhout, SSG President, focused on trends in PTFE coated guidewires. Here is a summary of our contributed content, as well as other guidewire coating trends we’re observing.

With cardiovascular disease affecting almost half of U.S. adults, medical device OEMs are constantly seeking technological advances that will help to improve medical procedures and patient outcomes. We are seeing a number of trends in PTFE coated guidewires relative to the application of medical polytetrafluoroethylene (PTFE) coatings, and the type of wire being coated. Because SSG has an on-site R&D coating lab that works closely with our customers and is constantly innovating, we stay on the forefront of medical device and component coating trends.

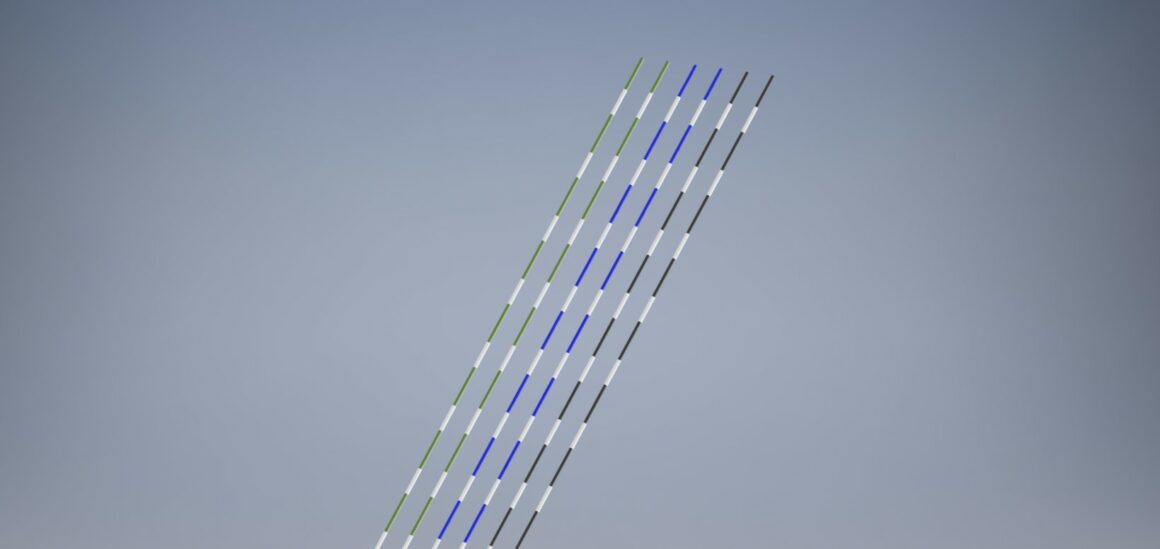

PTFE Coated Guidewires with PTFE Banding

There is an increased interest in adding a white PTFE banding marker on guidewires versus creating a band by having the PTFE ablated down to the metallic substrate, without damaging the wire. The PTFE coating method reduces friction and allows for tighter banding tolerances on the length of the guidewire, compared with the bare metal.

The white PTFE banding also provides greater contrast than the bare metal reflection against the coated area of the wire. This can help surgeons to gauge the depth of the wire during procedures, allowing for greater accuracy and better patient outcomes. There is a limit to which PTFE colors are used because of the required contrast. Most OEMs want white banding on green or blue PTFE-coated guidewires.

Due to the increased demand in banding, we are in the process of developing a system that will provide white banding on PTFE-coated cut-length guidewires up to 72 inches long. We currently can process guidewires up to 24 inches. Our tolerance on a 10-mm white band width is in the range of +/- .5 mm. We are in prototyping stages at this time and have excellent adhesion of the white band to the green or blue PTFE.

We have done this type of high contrast banding with hypotubes up to 15 inches long, but not on a 0.013-inch diameter guidewire that is 72 inches long. Although the much smaller diameter guidewire banding is indeed a challenge, we’re always up for challenges and figuring out solutions for our customers. Our R&D team has proved that it can be done.

We’re showing that the white banding is possible, as long as the bands are located within a 20-inch area on the guidewire. Our R&D team has also proven that we can do the banding with good repeatability on longer parts than originally thought.

PTFE coated guidewires with the white banding passes cytotoxicity testing and the band is relatively smooth on the PTFE surface.

This new PTFE guidewire banding technology has the added benefit of helping to lower production costs, due to reduced processing.

Metal Substrates Used in Guidewires

There is an increased acceptance of different metallic substrates used in PTFE coated guidewires, such as nitinol or 314 stainless steel. The diameter of guidewires is getting smaller and require a coating that reduces friction, so they can be pushed through the blood vessels more easily, reducing the risk of vascular damage.

Continuous Length PTFE Coated Guidewires on Spools

OEMs are increasingly asking SSG to provide the PTFE coatings on reel-to-reel continuous wire spools or cut-to-length guidewires. This helps to reduce their work-in-process costs, because they don’t have to do all the cutting and grinding prior to sending to us for coating.

Click this link to read the entire MPO article on the thrombectomy device market.

Contact us for more information about our guidewire coating technologies or to discuss your project with out technical consultant.