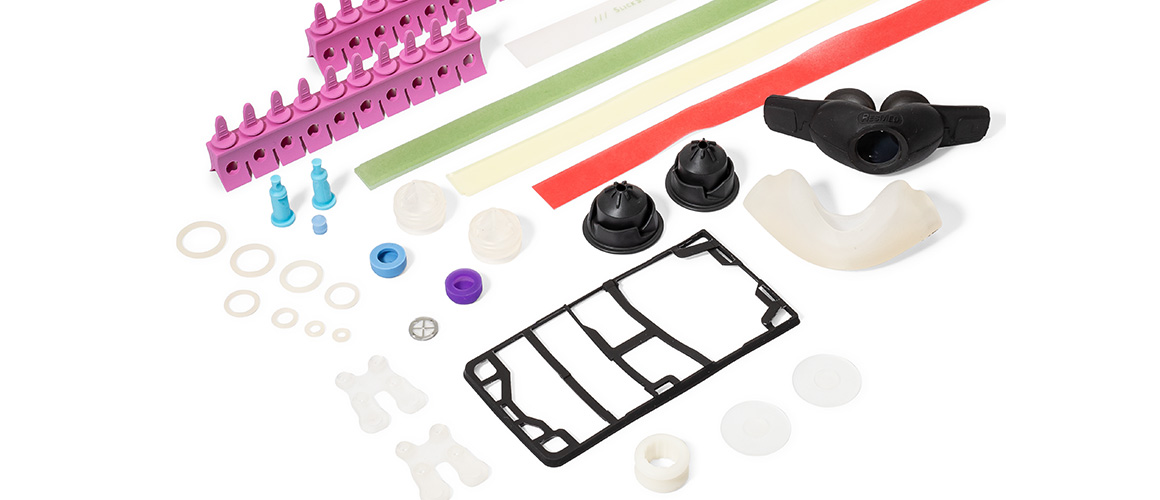

Silicone is generally thought of as a component with many end uses in diverse industries such as electronics, manufacturing, sporting goods, manufacturing, and consumer goods. It may surprise some to learn, then, that silicone plays a major role in the field of health care. A unique elastomer that’s efficient to manufacture, chemically inert, biocompatible, strong, nonconductive, and durable, it’s no wonder the medical industry embraced silicone for many medical device coating applications.

Much the same is true for polyisoprene rubber, the only non-synthetic rubber that has remained in commercial use for about a century. Completely biodegradable and able to meet biocompatibility requirements, this type of rubber is flexible, moldable, highly elastic, resists tearing, and stands up well when exposed to organic acids, alcohol, and a number of alkalis. In some specific scenarios, such as septum applications and injection sites, it is the ideal material to use.

Silicone is a perfect biomedical material for medical devices, except for one fault, it is too tacky for most applications. When silicone rubber comes in contact with other surfaces including other silicone it will resist motion with a coefficient of friction that exceeds 1.0.

Some solutions that have been used in the past are a thin dry coating like Parylene. Two major issues with Parylene is that it does not flex or bend with the silicone substrate, the other is that the Parylene can actually change the durometer of the silicone making it much harder than desired. Silicone oils, and other lubricants have been used on silicone but have limitations. While the oils are highly effective at lubricating the silicone, they tend to migrate away from the silicone surface and end up all over your device or work area, and the cost of these oils and lubricants that are approved by the FDA are extremely expensive.

Add Lubricity to Silicone for Medical Devices

Surface Solutions Group’s Slick Sil® is a translucent coating that chemically bonds with silicone rubber and reduces the coefficient of friction by 40% to 50%. Because of the chemical bond to the silicone, Slick Sil® will elongate, bend and flex with the substrate without the flaking and cracking that you may have experienced with using Parylene, and with it adhering to the silicone substrate you do not have to worry about it migrating away for the surfaces that need to be lubricated. This makes Slick Sil® an ideal addition to any silicone rubber that needs to be slippery.

Slick Sil® coating benefits at a glance:

- Forms a chemical bond with substrate, allows for coating to bend and flex

- Does not crack or flake like Parylene coatings

- Reduces the coefficient of friction by 40 – 50%

- PFAS-FREE coating

Slick Sil® is a unique coating in that it can be applied to many different types of silicone, and to many different durometers of silicone. It also has an advantage over Parylene as it does not need to be applied in a vacuum deposition chamber, it can be sprayed, dipped, or even brushed on to the silicone substrate. Another advantage of Slick Sil® is it can be infused with antimicrobial agents and has a kill rate of 99.9% for a long list of common bio-pathogens but have extremely low toxicity to people.

Contact us for more information or to discuss your silicone or project that requires medical device coating services.