Fluoropolymers are used nearly everywhere, in almost every major manufacturing sector. Those of us who formulate and apply the coatings, and our medical device manufacturing customers, understand the unique benefits they bring to everyday life, but most others do not. They have come under fire for allegedly causing harm to people and the environment. In...

Tag: medical device coatings

Medical Device Coatings Blog

Anatomy of Developing a New Sustainable, Compliant PTFE-Free Coating

What goes into developing coatings for medical devices? What drives the process? Understanding the factors that motivate manufacturers to seek out new and better coatings – such as our new GlideMed™ PTFE-free coating – and the processes that bring them to fruition can help medical device manufacturers and design engineers appreciate the big picture. Many...

Answering Your Common Medical Device Coating Questions

With more than six decades of coating expertise, the Surface Solutions Group team is often asked questions about medical grade PTFE coatings their application to a variety of medical devices and components. Here are the answers to some of the more common medical device coating questions we hear. Q: What is PTFE coating? A: PTFE, or...

SSG Completes ISO 13485:2016 Audit with Zero-Findings, 3 Years in a Row!

As an ISO 13485:2016 certified company, Surface Solutions Group strives to constantly meet or exceed our customer’s requirements in quality, service and delivery. We monitor and maintain all of these and other critical operational statistics daily. SSG participates in routine Quality Management System audits, independently conducted by NSF ISR. The last audit concluded on July...

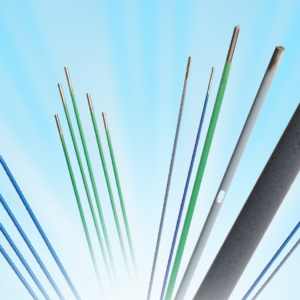

Advantages of Coating Reel-to-Reel, Continuous Wire

For medical OEMs in need of precision application of coatings for reel-to-reel, continuous wire, Surface Solutions Group (SSG) has the experience, know-how and equipment to make it happen. Whether the application involves continuous round wire, tubing, or cables, our team takes care to apply Polytetrafluoroethylene (PTFE) coatings to reel-to-reel wires at 0.0001- 0.0003 inches per...